What are the product features of resistor manufacturers?

What are the Product Features of Resistor Manufacturers?

I. Introduction

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage and current levels, ensuring that electronic devices operate safely and effectively. By providing a specific resistance value, resistors help to manage the performance of various electronic components, making them indispensable in modern electronics.

B. Importance of Resistors in Electronic Circuits

In electronic circuits, resistors play a crucial role in protecting sensitive components from excessive current, dividing voltages, and setting bias points for transistors. They are found in virtually every electronic device, from simple household appliances to complex computing systems. The reliability and performance of these devices often hinge on the quality and specifications of the resistors used.

C. Overview of Resistor Manufacturers

The market for resistors is diverse, with numerous manufacturers offering a wide range of products tailored to different applications. These manufacturers focus on various aspects, including material composition, manufacturing processes, and customization options, to meet the specific needs of their customers. Understanding the product features offered by resistor manufacturers is essential for engineers and designers when selecting the right components for their projects.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that cannot be changed. They are widely used in electronic circuits for various applications.

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable over time.

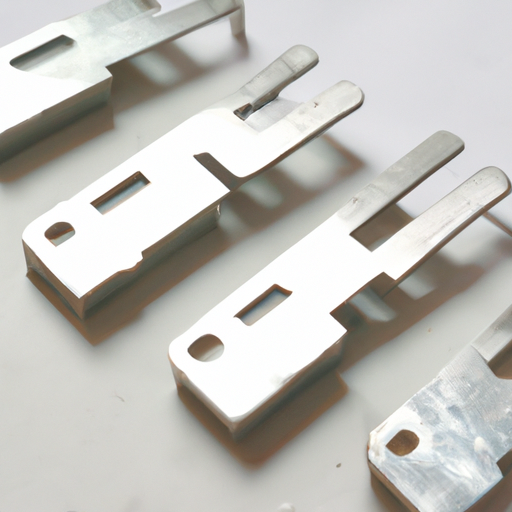

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability, lower noise, and tighter tolerances compared to carbon composition resistors, making them suitable for precision applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications. They are known for their accuracy and stability.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: These are commonly used for adjusting voltage levels in circuits, such as volume controls in audio equipment. They consist of a resistive element and a movable contact.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications requiring higher power ratings.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, commonly used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, making them useful in light-sensing applications.

3. **Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes by changing resistance with voltage levels, often used in surge protection devices.

III. Key Product Features of Resistor Manufacturers

A. Resistance Value Range

1. **Standard Values**: Resistor manufacturers typically offer a range of standard resistance values, adhering to the E12 and E24 series, which provide a set of preferred numbers for easy selection.

2. **Custom Values**: Many manufacturers also provide custom resistance values to meet specific application requirements, allowing engineers to design circuits with precision.

B. Tolerance Levels

1. **Importance of Tolerance**: Tolerance indicates how much the actual resistance can vary from the specified value. It is crucial for ensuring circuit performance and reliability.

2. **Common Tolerance Ratings**: Resistors are available with various tolerance ratings, such as ±1%, ±5%, and ±10%, with precision resistors offering tighter tolerances of ±0.1% or better.

C. Power Rating

1. **Definition and Importance**: Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is essential for preventing component failure in high-power applications.

2. **Power Rating Options**: Resistors come in various power ratings, typically ranging from 1/8 watt to several hundred watts, depending on the type and application.

D. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: The temperature coefficient indicates how much a resistor's resistance changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C).

2. **Impact on Performance**: A low temperature coefficient is desirable for precision applications, as it ensures stable performance across varying temperatures.

E. Size and Form Factor

1. **Surface Mount vs. Through-Hole**: Resistors are available in surface mount (SMD) and through-hole configurations. SMD resistors are smaller and suitable for compact designs, while through-hole resistors are easier to handle and solder.

2. **Miniaturization Trends**: The trend towards miniaturization in electronics has led to the development of smaller resistor packages, allowing for more compact circuit designs.

F. Material Composition

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal, or metal oxide, affects the resistor's performance characteristics, including stability and noise levels.

2. **Insulating Materials**: Insulating materials used in resistor construction impact thermal performance and reliability, with ceramic and epoxy being common choices.

G. Environmental Ratings

1. **RoHS Compliance**: Many manufacturers adhere to the Restriction of Hazardous Substances (RoHS) directive, ensuring that their products are free from harmful substances.

2. **Operating Temperature Range**: Resistors are rated for specific operating temperature ranges, which is critical for ensuring reliable performance in various environments.

3. **Moisture and Humidity Resistance**: Environmental ratings also include moisture and humidity resistance, which are essential for applications in harsh conditions.

IV. Quality Assurance and Testing

A. Manufacturing Standards

1. **ISO Certifications**: Many resistor manufacturers hold ISO certifications, ensuring that their products meet international quality management standards.

2. **Industry Standards (e.g., IEC, JIS)**: Compliance with industry standards ensures that resistors meet specific performance and safety criteria.

B. Testing Procedures

1. **Electrical Testing**: Manufacturers conduct electrical testing to verify resistance values, power ratings, and tolerance levels.

2. **Environmental Testing**: Environmental testing assesses how resistors perform under various conditions, including temperature extremes and humidity.

3. **Reliability Testing**: Reliability testing evaluates the long-term performance of resistors, ensuring they can withstand the rigors of their intended applications.

V. Customization and Design Services

A. Custom Resistor Solutions

1. **Tailored Specifications**: Many manufacturers offer custom resistor solutions, allowing engineers to specify unique resistance values, tolerances, and power ratings.

2. **Prototyping Services**: Prototyping services enable designers to test custom resistor designs before full-scale production, ensuring that specifications meet application requirements.

B. Design Support

1. **Simulation Tools**: Manufacturers often provide simulation tools to help engineers model circuit behavior and optimize resistor selection.

2. **Application Engineering**: Application engineering support assists customers in selecting the right resistors for their specific applications, enhancing overall design efficiency.

VI. Supply Chain and Distribution

A. Global Reach

1. **Manufacturing Locations**: Many resistor manufacturers have global manufacturing facilities, allowing them to meet demand across different regions.

2. **Distribution Networks**: A robust distribution network ensures that resistors are readily available to customers, minimizing lead times and enhancing supply chain efficiency.

B. Lead Times and Availability

1. **Stock vs. Custom Orders**: Manufacturers typically maintain stock of standard resistors while offering lead times for custom orders, which can vary based on specifications.

2. **Impact of Global Supply Chain Issues**: Recent global supply chain challenges have highlighted the importance of reliable sourcing and distribution strategies for resistor manufacturers.

VII. Trends and Innovations in Resistor Manufacturing

A. Advances in Materials Science

Innovations in materials science have led to the development of new resistor types with improved performance characteristics, such as higher power ratings and better thermal stability.

B. Smart Resistors and IoT Integration

The rise of the Internet of Things (IoT) has spurred the development of smart resistors that can communicate data, enabling more intelligent and responsive electronic systems.

C. Sustainability Initiatives

Many manufacturers are adopting sustainability initiatives, focusing on eco-friendly materials and processes to reduce their environmental impact.

VIII. Conclusion

A. Summary of Key Features

Understanding the product features of resistor manufacturers is essential for selecting the right components for electronic designs. Key features include resistance value range, tolerance levels, power ratings, temperature coefficients, size and form factor, material composition, and environmental ratings.

B. Importance of Choosing the Right Resistor Manufacturer

Choosing the right resistor manufacturer can significantly impact the performance and reliability of electronic devices. Factors such as quality assurance, customization options, and supply chain efficiency should be considered when making this decision.

C. Future Outlook for Resistor Technology

As technology continues to evolve, resistor manufacturers will likely focus on innovation, sustainability, and meeting the demands of increasingly complex electronic systems. The future of resistor technology promises exciting advancements that will enhance the performance and capabilities of electronic devices.

IX. References

A. Industry Publications

- Electronic Design Magazine

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Manufacturer Websites

- Vishay Intertechnology

- Yageo Corporation

C. Technical Journals and Articles

- Journal of Electronic Materials

- Journal of Applied Physics

This comprehensive overview of the product features of resistor manufacturers highlights the critical aspects that engineers and designers must consider when selecting resistors for their applications. By understanding these features, professionals can make informed decisions that enhance the performance and reliability of their electronic designs.