What kind of product are wirewound resistors?

What Kind of Product Are Wirewound Resistors?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, wirewound resistors stand out due to their unique construction and characteristics. This article aims to provide a comprehensive understanding of wirewound resistors, exploring their definition, construction, advantages, disadvantages, applications, and future trends. By the end, readers will have a clearer picture of what wirewound resistors are and their significance in modern electronics.

II. Understanding Resistors

A. Basic Function of Resistors in Electrical Circuits

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for protecting sensitive components, dividing voltages, and setting bias points in transistors. By providing resistance, they help maintain the desired current levels, ensuring that circuits function correctly.

B. Types of Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most common type used in circuits.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these allow users to adjust the resistance value as needed.

3. **Specialty Resistors**: This category includes various types of resistors designed for specific applications, such as thermistors and photoresistors.

C. Role of Wirewound Resistors Among Other Types

Wirewound resistors are a type of fixed resistor made by winding a metal wire around a core. They are known for their high precision and ability to handle significant power loads, making them suitable for various applications where reliability and accuracy are paramount.

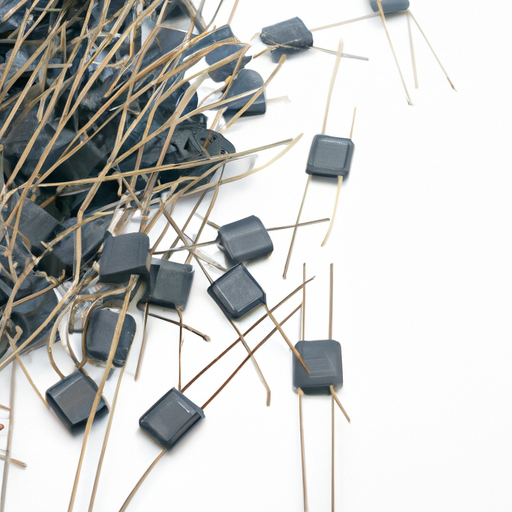

III. Construction of Wirewound Resistors

A. Materials Used

1. **Wire Materials**: Wirewound resistors are typically made from alloys such as nickel-chromium or copper-nickel, which provide excellent conductivity and resistance properties.

2. **Insulating Materials**: Insulation is crucial to prevent short circuits and ensure safety. Common insulating materials include ceramic and epoxy.

B. Manufacturing Process

1. **Winding the Wire**: The manufacturing process begins with winding the resistive wire around a non-conductive core. The number of turns and the wire's thickness determine the resistor's final resistance value.

2. **Mounting and Encapsulation**: After winding, the resistor is mounted onto a substrate and encapsulated to protect it from environmental factors.

C. Design Variations

1. **Different Shapes and Sizes**: Wirewound resistors come in various shapes, including cylindrical and rectangular forms, to fit different applications.

2. **Power Ratings and Resistance Values**: They are available in a wide range of power ratings (from a fraction of a watt to several hundred watts) and resistance values (from ohms to megaohms).

IV. Characteristics of Wirewound Resistors

A. Resistance Range and Tolerance

Wirewound resistors typically offer a resistance range from a few ohms to several megaohms, with tolerances as low as 0.1%. This high precision makes them ideal for applications requiring exact resistance values.

B. Power Rating and Thermal Management

These resistors can handle high power loads, often exceeding 100 watts. Their construction allows for effective heat dissipation, which is critical in preventing overheating and ensuring longevity.

C. Temperature Coefficient

Wirewound resistors have a low temperature coefficient, meaning their resistance value changes minimally with temperature fluctuations. This stability is essential in precision applications.

D. Inductance and Its Implications

One downside of wirewound resistors is their inherent inductance, which can affect performance in high-frequency applications. This characteristic can lead to unwanted oscillations and signal distortion.

E. Stability and Reliability

Wirewound resistors are known for their stability and reliability over time, making them suitable for critical applications in various industries.

V. Advantages of Wirewound Resistors

A. High Precision and Accuracy

Wirewound resistors provide excellent precision, making them ideal for applications where exact resistance values are crucial.

B. Excellent Thermal Stability

Their ability to maintain performance across a wide temperature range ensures consistent operation in varying environmental conditions.

C. Ability to Handle High Power Loads

Wirewound resistors can manage significant power levels, making them suitable for high-power applications such as power supplies and motor control circuits.

D. Durability and Longevity

The robust construction of wirewound resistors contributes to their durability, allowing them to withstand harsh conditions and extended use.

E. Versatility in Applications

Wirewound resistors are used in a wide range of applications, from industrial machinery to consumer electronics, due to their adaptability and performance.

VI. Disadvantages of Wirewound Resistors

A. Size and Weight Considerations

Wirewound resistors tend to be larger and heavier than other types of resistors, which can be a drawback in compact electronic designs.

B. Inductance Issues in High-Frequency Applications

As mentioned earlier, the inductance of wirewound resistors can lead to performance issues in high-frequency circuits, limiting their use in certain applications.

C. Cost Compared to Other Resistor Types

Wirewound resistors are generally more expensive than carbon or metal film resistors, which may be a consideration for budget-sensitive projects.

D. Limited Resistance Values in Some Cases

While they offer a wide range of resistance values, wirewound resistors may not be available in every desired value, potentially requiring custom solutions.

VII. Applications of Wirewound Resistors

A. Industrial Applications

1. **Power Supplies**: Wirewound resistors are commonly used in power supply circuits to regulate voltage and current.

2. **Motor Control Circuits**: They help manage the current flow in motor control applications, ensuring efficient operation.

B. Consumer Electronics

1. **Audio Equipment**: High-fidelity audio systems often utilize wirewound resistors for their precision and low noise characteristics.

2. **Measurement Devices**: Instruments that require accurate readings, such as multimeters, frequently incorporate wirewound resistors.

C. Automotive Applications

Wirewound resistors are used in various automotive systems, including braking and engine control systems, where reliability is critical.

D. Medical Devices

In medical equipment, precision and reliability are paramount, making wirewound resistors a preferred choice for devices like diagnostic machines.

E. Aerospace and Military Applications

The durability and stability of wirewound resistors make them suitable for aerospace and military applications, where performance under extreme conditions is essential.

VIII. Comparison with Other Resistor Types

A. Wirewound vs. Carbon Film Resistors

While carbon film resistors are cost-effective and suitable for low-power applications, wirewound resistors offer higher precision and power handling capabilities.

B. Wirewound vs. Metal Film Resistors

Metal film resistors provide excellent stability and low noise, but wirewound resistors excel in high-power applications.

C. Wirewound vs. Surface Mount Resistors

Surface mount resistors are compact and suitable for high-density applications, but wirewound resistors are preferred for their power handling and precision.

D. Situational Advantages and Disadvantages

The choice between wirewound and other resistor types depends on the specific requirements of the application, including power, size, and precision needs.

IX. Future Trends and Innovations

A. Advances in Materials and Manufacturing Techniques

Ongoing research into new materials and manufacturing processes aims to enhance the performance and reduce the size of wirewound resistors.

B. Emerging Applications in Technology

As technology evolves, wirewound resistors are finding new applications in areas such as renewable energy systems and electric vehicles.

C. Environmental Considerations and Sustainability

The electronics industry is increasingly focusing on sustainability, and wirewound resistors are being designed with eco-friendly materials and processes in mind.

X. Conclusion

Wirewound resistors are a vital component in the electronics landscape, offering high precision, durability, and versatility across various applications. Their unique construction and characteristics make them indispensable in many critical systems, from industrial machinery to consumer electronics. As technology continues to advance, wirewound resistors will likely evolve, finding new applications and improving their performance. Understanding these components is essential for anyone involved in electronics, and further exploration of resistors can lead to a deeper appreciation of their role in modern technology.

XI. References

For those interested in delving deeper into the world of wirewound resistors and resistors in general, consider exploring the following resources:

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe.

2. "Resistor Technology: A Comprehensive Guide" by Jane Smith.

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By understanding the intricacies of wirewound resistors, engineers and hobbyists alike can make informed decisions in their electronic designs and applications.